Our Products

Countries We Export To

EIL Approved Flanges Manufacturer, Stockist, and Supplier in India

Pinnacle Metal Industries is highly acknowledged as an excellent quality Flanges manufacturer in Mumbai, India. The Flanges are available in different grades, materials, sizes, and finishes. AMS has a professional team that oversees the entire production process, ensuring the supply of defect-free products. The fabrication of Flanges is carried out using the latest technology, modern tools, adhering to raw material quality standards, and in accordance with industrial norms.

Flanges are mechanical components used to connect pipes, valves, pumps, and other equipment to form a piping system. They provide a means for easy assembly, disassembly, and maintenance of the system while also allowing for proper sealing and alignment of the connected components. This alloy gives Flanges their unique properties, including corrosion resistance, durability, and strength. AMS specialize in trading and supplying a quality array of – Flat face (ff), Raised face (ff). Flanges are manufactured and tested as per globally approved quality standards under the strict supervision of highly qualified experts.

EIL Approved Manufacturer of Flanges

Pinnacle Metal Industries (PMI) proudly announces its approval by Engineers India Limited (EIL) as a certified manufacturer of Stainless Steel and Carbon Steel Flanges. This prestigious certification is a mark of trust, quality, and compliance with the highest industry standards. By achieving EIL approval, PMI demonstrates its capability to deliver products that meet stringent engineering, safety, and reliability requirements for critical projects across oil & gas, petrochemical, power, and infrastructure sectors. Choosing PMI means partnering with a manufacturer whose flanges are not only globally competitive but also backed by one of India’s most respected engineering authorities.

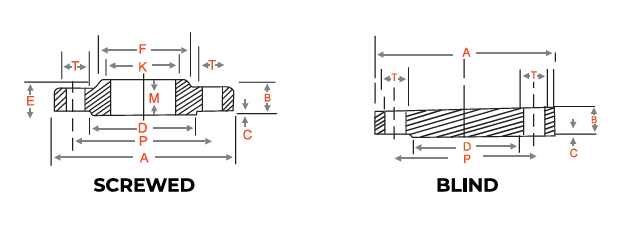

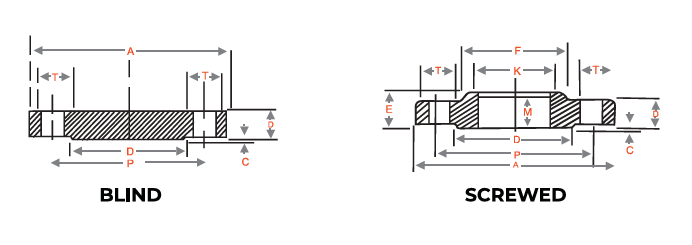

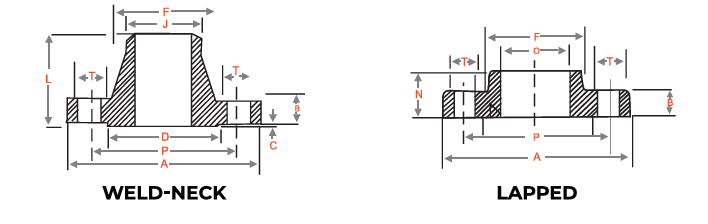

Types of Flanges

Specifications of Flanges

| Flanges | Specifications |

|---|---|

| Material | Stainless Steel, Duplex, Super Duplex, Carbon Steel & Alloy Steel |

| Standards | ASTM/ ASME SA/ A182, SA/ A105 |

| Dimension Standards | ASME B16.5, ASME B16.47 SERIES A & B, DIN, ISO, BS-10 TABLE D, E, F, H |

| Size | 1/2″ to 60″ NB |

| Pressure Ratings | 150, 300, 900, 1500, 2500 lb, PN 6, PN 10, PN 16, PN 25, PN 40, PN 100 |

| Face | Flat face (ff), Raised face (ff) |

| USP | Custom made flanges as per drawing |

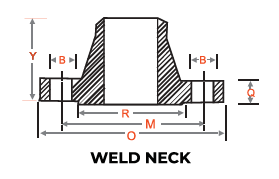

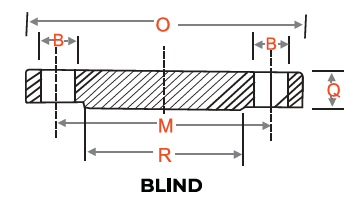

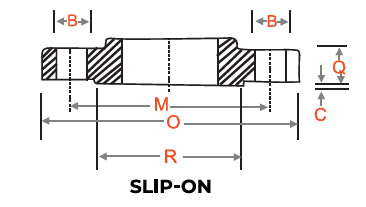

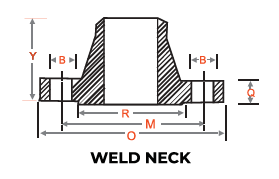

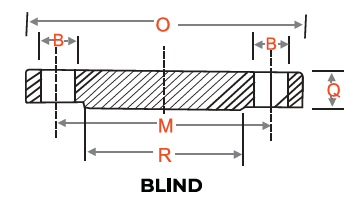

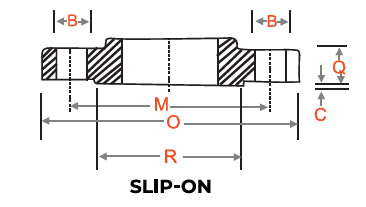

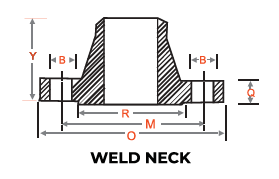

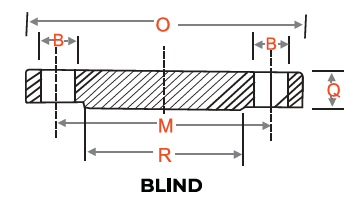

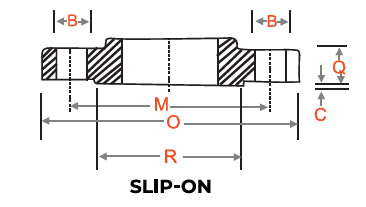

FORGED FLANGES - STANDARD DIMENSION

CLASS 150 LBS

| NOMINAL PIPE SIZE (NB) | OUTSIDE DIA OF FLANGE | MIN THICKNESS OF FLANGE | OVERALL LENGTH | BOLT CIRCLE | NO. AND SIZE OF HOLES | OD OF RAISED FACE | |||

| WELDING NECK | SLIP-ON & SOCKET WELDING | LAP JOINT | |||||||

| O | Q | Y | DIA.M | NO | B | R | |||

| 15 | 89 | 11.2 | 47.6 | 15.9 | 15.9 | 60.5 | 4 | 15 | 35 |

| 20 | 98 | 12.7 | 52.4 | 15.9 | 15.9 | 70 | 4 | 15 | 43 |

| 25 | 108 | 14.3 | 55.6 | 17.5 | 17.5 | 79.5 | 4 | 15 | 51 |

| 32 | 117 | 15.9 | 57.2 | 20.6 | 20.6 | 89 | 4 | 15 | 64 |

| 40 | 127 | 17.5 | 61.9 | 22.2 | 22.2 | 98.5 | 4 | 15 | 73 |

| 50 | 152 | 19.1 | 63.5 | 25.4 | 25.4 | 120.5 | 4 | 19 | 92 |

| 65 | 178 | 22.3 | 69.8 | 28.6 | 28.6 | 139.5 | 4 | 19 | 105 |

| 80 | 190 | 23.9 | 69.8 | 30.2 | 30.2 | 152.5 | 4 | 19 | 127 |

| 90 | 216 | 23.9 | 71.4 | 31.8 | 31.8 | 178 | 8 | 19 | 140 |

| 100 | 229 | 23.9 | 76.2 | 33.3 | 33.3 | 190.5 | 8 | 19 | 157 |

| 125 | 254 | 23.9 | 88.9 | 36.5 | 36.5 | 216 | 8 | 22 | 186 |

| 150 | 279 | 25.4 | 88.9 | 39.7 | 39.7 | 241.5 | 8 | 22 | 216 |

| 200 | 343 | 28.6 | 101.6 | 44.4 | 44.4 | 298.5 | 8 | 22 | 270 |

| 250 | 406 | 30.2 | 101.6 | 49.2 | 49.2 | 326 | 12 | 25 | 324 |

| 300 | 483 | 31.8 | 114.3 | 55.6 | 55.6 | 432 | 12 | 25 | 381 |

| 350 | 533 | 35 | 127 | 57.2 | 79.4 | 476 | 12 | 29 | 413 |

| 400 | 597 | 36.6 | 127 | 63.5 | 87.3 | 539.5 | 16 | 29 | 470 |

| 450 | 635 | 39.7 | 139.7 | 68.3 | 96.8 | 578 | 16 | 32 | 533 |

| 500 | 698 | 42.9 | 144.5 | 73 | 103.2 | 635 | 20 | 32 | 584 |

| 600 | 813 | 47.7 | 152.4 | 82.6 | 111.1 | 749.5 | 20 | 35 | 692 |

CLASS 300 LBS

| NOMINAL PIPE SIZE (NB) | OUTSIDE DIA OF FLANGE | MINIMUM THICKNESS OF FLANGE | OVERALL LENGTH | BOLT CIRCLE | NO. AND SIZE OF HOLES | OD OF RAISED FACE | |||

| WELDING NECK | SLIP-ON & SOCKET WELDING | LAP JOINT | |||||||

| O | Q | Y | DIA.M | NO | B | R | |||

| 15 | 95 | 14.3 | 52.4 | 22.2 | 22.2 | 66.5 | 4 | 15 | 35 |

| 20 | 117 | 15.9 | 57.2 | 25.4 | 25.4 | 82.5 | 4 | 19 | 43 |

| 25 | 124 | 17.5 | 61.9 | 27 | 27 | 89.5 | 4 | 19 | 51 |

| 32 | 133 | 19.1 | 65.1 | 27 | 27 | 98.5 | 4 | 19 | 64 |

| 40 | 156 | 20.7 | 68.3 | 30.2 | 30.2 | 114.5 | 4 | 22 | 73 |

| 50 | 165 | 22.3 | 69.8 | 33.3 | 33.3 | 127 | 8 | 19 | 92 |

| 65 | 190 | 25.4 | 76.2 | 38.1 | 38.1 | 149 | 8 | 22 | 105 |

| 80 | 210 | 28.6 | 79.4 | 42.9 | 42.9 | 168 | 8 | 22 | 127 |

| 90 | 229 | 30.2 | 81.8 | 44.5 | 44.5 | 184 | 8 | 22 | 140 |

| 100 | 254 | 31.8 | 85.7 | 47.6 | 47.6 | 200 | 8 | 22 | 157 |

| 125 | 279 | 35 | 98.4 | 50.8 | 50.8 | 235 | 8 | 22 | 186 |

| 150 | 313 | 36.6 | 98.4 | 52.4 | 52.4 | 270 | 12 | 22 | 216 |

| 200 | 381 | 41.3 | 111.1 | 61.9 | 61.9 | 330 | 12 | 25 | 270 |

| 250 | 444 | 47.7 | 117.5 | 66.7 | 66.7 | 387.5 | 16 | 29 | 324 |

| 300 | 521 | 50.8 | 130.2 | 73 | 73 | 451 | 16 | 32 | 381 |

| 350 | 584 | 54 | 142.9 | 76.2 | 76.2 | 514.5 | 20 | 32 | 413 |

| 400 | 648 | 57.2 | 146 | 82.6 | 82.6 | 571.5 | 20 | 35 | 470 |

| 450 | 711 | 60.4 | 158.8 | 88.9 | 88.9 | 628.5 | 24 | 35 | 533 |

| 500 | 775 | 63.5 | 161.9 | 95.2 | 95.2 | 686 | 24 | 35 | 584 |

| 600 | 914 | 69.9 | 168.3 | 106.4 | 106.4 | 813 | 24 | 41 | 692 |

CLASS 600 LBS

| NOMINAL PIPE SIZE (NB) | OUTSIDE DIA OF FLANGE | MINIMUM THICKNESS OF FLANGE | OVERALL LENGTH | BOLT CIRCLE | NO. AND SIZE OF HOLES | OD OF RAISED FACE | |||

| WELDING NECK | SLIP-ON & SOCKET WELDING | LAP JOINT | |||||||

| O | Q | Y | DIA.M | NO | B | R | |||

| 15 | 95 | 14.3 | 52.4 | 22.2 | 22.2 | 66.5 | 4 | 15 | 35 |

| 20 | 117 | 15.9 | 57.2 | 25.4 | 25.4 | 82.5 | 4 | 19 | 43 |

| 25 | 124 | 17.5 | 61.9 | 27 | 27 | 89.5 | 4 | 19 | 51 |

| 32 | 133 | 20.7 | 66.7 | 28.6 | 28.6 | 98.5 | 4 | 19 | 64 |

| 40 | 156 | 22.3 | 96.8 | 31.8 | 31.8 | 114.5 | 4 | 22 | 73 |

| 50 | 165 | 25.4 | 73 | 36.5 | 36.5 | 127 | 8 | 19 | 92 |

| 65 | 190 | 28.6 | 79.4 | 41.3 | 41.3 | 149 | 8 | 22 | 105 |

| 80 | 210 | 31.8 | 82.6 | 46 | 46 | 168 | 8 | 22 | 127 |

| 90 | 229 | 35 | 85.7 | 49.2 | 49.2 | 184 | 8 | 25 | 140 |

| 100 | 273 | 38.1 | 101.6 | 54 | 54 | 216 | 8 | 25 | 157 |

| 125 | 330 | 44.5 | 114.3 | 60.3 | 60.3 | 266.5 | 8 | 29 | 186 |

| 150 | 356 | 47.7 | 117.5 | 66.7 | 66.7 | 292 | 12 | 29 | 216 |

| 200 | 419 | 55.6 | 133.4 | 76.2 | 76.2 | 349 | 12 | 32 | 270 |

| 250 | 508 | 63.5 | 152.4 | 85.7 | 115.1 | 432..0 | 16 | 35 | 324 |

| 300 | 559 | 66.7 | 155.6 | 92.1 | 111.1 | 489 | 20 | 35 | 381 |

| 350 | 603 | 69.9 | 165.1 | 93.7 | 117.5 | 527 | 20 | 38 | 413 |

| 400 | 686 | 76.2 | 177.8 | 106.4 | 127 | 603 | 20 | 41 | 470 |

| 450 | 743 | 82.6 | 184.2 | 117.6 | 139.7 | 654 | 20 | 45 | 533 |

| 500 | 813 | 88.9 | 190.5 | 127 | 165.1 | 724 | 24 | 45 | 584 |

| 600 | 940 | 101.6 | 203.2 | 139.7 | 184.2 | 838 | 24 | 51 | 692 |

CLASS 900 LBS

| NOMINAL PIPE SIZE (NB) | OUTSIDE DIA OF FLANGE | MINIMUM THICKNESS OF FLANGE | OVERALL LENGTH | BOLT CIRCLE | NO. AND SIZE OF HOLES | OD OF RAISED FACE | |||

| WELDING NECK | SLIP-ON & SOCKET WELDING | LAP JOINT | |||||||

| O | Q | Y | DIA.M | NO | B | R | |||

| 15 | 121 | 22.3 | 60.3 | 31.8 | 31.8 | 82.5 | 4 | 22 | 35 |

| 20 | 130 | 25.4 | 69.8 | 34.9 | 34.9 | 89 | 4 | 22 | 43 |

| 25 | 149 | 28.6 | 73 | 41.3 | 41.3 | 101.5 | 4 | 25 | 51 |

| 32 | 159 | 28.6 | 73 | 41.3 | 41.3 | 111 | 4 | 25 | 64 |

| 40 | 178 | 31.8 | 82.6 | 44.4 | 44.4 | 124 | 4 | 29 | 73 |

| 50 | 216 | 38.1 | 101.6 | 57.2 | 57.2 | 165 | 8 | 25 | 92 |

| 65 | 244 | 41.3 | 104.8 | 63.5 | 63.5 | 190.5 | 8 | 25 | 105 |

| 80 | 241 | 38.1 | 101.6 | 54 | 54 | 190.5 | 8 | 25 | 127 |

| 100 | 292 | 44.5 | 114.3 | 69.8 | 69.8 | 235 | 8 | 32 | 157 |

| 125 | 349 | 50.8 | 127 | 79.4 | 79.4 | 279 | 8 | 35 | 186 |

| 150 | 381 | 55.6 | 139.7 | 85.7 | 85.7 | 317.5 | 12 | 32 | 216 |

| 200 | 470 | 68.5 | 161.5 | 101.8 | 114.3 | 393.5 | 12 | 38 | 270 |

| 250 | 546 | 69.9 | 184.2 | 108 | 127 | 470 | 16 | 38 | 324 |

| 300 | 610 | 79.4 | 200 | 117.5 | 142.9 | 533.5 | 20 | 38 | 381 |

| 350 | 641 | 85.8 | 212.7 | 130.2 | 155.6 | 559 | 20 | 41 | 413 |

| 400 | 705 | 88.9 | 215.8 | 133.4 | 165.1 | 616 | 20 | 45 | 470 |

| 450 | 787 | 101.6 | 228.6 | 152.4 | 190.5 | 686 | 20 | 51 | 533 |

| 500 | 857 | 108 | 247.6 | 158.8 | 209.6 | 749.5 | 20 | 54 | 584 |

| 600 | 1041 | 139.7 | 292.1 | 203.2 | 266.7 | 901.5 | 20 | 67 | 692 |

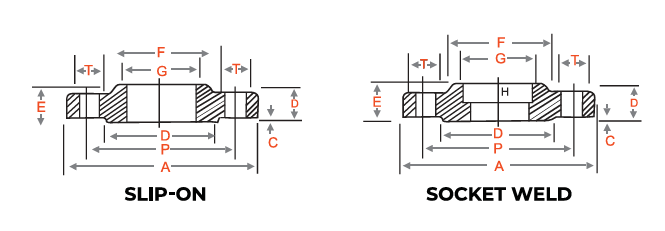

CLASS 1500 LBS

| NB | A | B | C | D | E | F | G | H | J | K | L | M | N | O | P | R | T | No. of Holes |

| 15 | 121 | 22.2 | 6.4 | 35 | 32 | 38 | 22.4 | 9.5 | 21.3 | 23.5 | 60 | 22 | 32 | 23 | 82.6 | 3 | 22.2 | 4 |

| 20 | 130 | 25.4 | 6.4 | 43 | 35 | 44 | 27.7 | 11 | 26.7 | 29 | 70 | 25 | 35 | 28 | 88.9 | 3 | 22.2 | 4 |

| 25 | 149 | 28.6 | 6.4 | 51 | 41 | 52 | 34.5 | 12.5 | 33.4 | 36 | 73 | 29 | 41 | 35 | 101.6 | 3 | 25.4 | 4 |

| 32 | 159 | 28.6 | 6.4 | 64 | 41 | 64 | 43.2 | 14.5 | 42.2 | 44.5 | 73 | 30 | 41 | 43.5 | 111.1 | 5 | 25.4 | 4 |

| 40 | 178 | 31.8 | 6.4 | 73 | 44 | 70 | 49.5 | 16 | 48.3 | 50.5 | 83 | 32 | 44 | 50 | 123.8 | 6.5 | 28.6 | 4 |

| 50 | 216 | 38.1 | 6.4 | 92 | 57 | 105 | 62 | 17.5 | 60.3 | 63.5 | 102 | 38 | 57 | 62.5 | 165.1 | 8 | 25.4 | 8 |

| 65 | 244 | 41.3 | 6.4 | 105 | 64 | 124 | 74.7 | 19 | 73 | 76 | 105 | 48 | 64 | 75 | 190.5 | 8 | 28.6 | 8 |

| 80 | 267 | 47.6 | 6.4 | 127 | 73 | 133 | – | – | 88.9 | 92 | 117 | 51 | 73 | 91.5 | 203.2 | 9.5 | 31.8 | 8 |

| 100 | 311 | 54 | 6.4 | 157 | 91 | 162 | – | – | 114.3 | 118 | 124 | 57 | 91 | 17 | 241.3 | 11 | 34.9 | 8 |

| 125 | 375 | 73 | 6.4 | 186 | 105 | 197 | – | – | 141.3 | 145 | 156 | 64 | 105 | 145 | 292.1 | 11 | 41.3 | 8 |

| 150 | 394 | 82.6 | 6.4 | 216 | 119 | 229 | – | – | 168.3 | 171 | 171 | 70 | 119 | 171 | 317.5 | 12.5 | 38.1 | 12 |

| 200 | 483 | 92.1 | 6.4 | 270 | 143 | 292 | – | – | 219.1 | 222 | 213 | 76 | 143 | 222 | 393.7 | 12.5 | 44.4 | 12 |

| 250 | 584 | 108 | 6.4 | 324 | 159 | 368 | – | – | 273 | 276 | 254 | 84 | 178 | 277 | 482.6 | 12.5 | 50.8 | 12 |

| 300 | 673 | 123.8 | 6.4 | 381 | 181 | 451 | – | – | 323.9 | 329 | 283 | 92 | 219 | 328 | 571.5 | 12.5 | 54 | 16 |

| 350 | 749 | 133.4 | 6.4 | 413 | – | 495 | – | – | 356.6 | – | 298 | – | 241 | 360 | 635 | 12.5 | 60.3 | 16 |

| 400 | 826 | 146.1 | 6.4 | 470 | – | 552 | – | – | 406.4 | – | 311 | – | 260 | 411 | 704.8 | 12.5 | 6.7 | 16 |

| 450 | 914 | 161.9 | 6.4 | 533 | – | 597 | – | – | 457.2 | – | 327 | – | 276 | 462 | 774.7 | 12.5 | 73 | 16 |

| 500 | 984 | 178 | 6.4 | 584 | – | 641 | – | – | 508 | – | 356 | – | 292 | 514 | 831.8 | 12.5 | 79.4 | 16 |

| 600 | 1168 | 203 | 6.4 | 692 | – | 762 | – | – | 609.6 | – | 406 | – | 330 | 616 | 990.6 | 12.5 | 92 | 16 |

CLASS 2500 LBS

| NB | A | B | C | D | E | F | G | H | J | K | L | M | N | O | P | R | T | NO. OF HOLES |

| 15 | 133 | 30.2 | 6.4 | 35 | 40 | 43 | – | – | 21.3 | 23.5 | 73 | 29 | 40 | 23 | 88.9 | 3 | 22.2 | 4 |

| 20 | 140 | 31.7 | 6.4 | 43 | 43 | 51 | – | – | 26.7 | 29 | 79 | 32 | 43 | 28 | 95.2 | 3 | 22.2 | 4 |

| 25 | 159 | 34.9 | 6.4 | 51 | 48 | 57 | – | – | 33.4 | 35 | 89 | 35 | 48 | 35 | 107.9 | 3 | 25.4 | 4 |

| 32 | 184 | 38.1 | 6.4 | 64 | 52 | 73 | – | – | 42.2 | 44.5 | 95 | 38 | 52 | 43.5 | 130.2 | 5 | 28.6 | 4 |

| 40 | 203 | 44.4 | 6.4 | 73 | 60 | 79 | – | – | 48.3 | 50.5 | 111 | 44 | 60 | 50 | 146 | 6.5 | 31.8 | 4 |

| 50 | 235 | 50.8 | 6.4 | 92 | 70 | 95 | – | – | 60.3 | 63.5 | 127 | 51 | 70 | 62.5 | 171.4 | 8 | 28.6 | 8 |

| 65 | 267 | 57.1 | 6.4 | 105 | 79 | 114 | – | – | 73 | 76 | 143 | 57 | 79 | 75.5 | 196.8 | 8 | 31.8 | 8 |

| 80 | 305 | 66.7 | 6.4 | 127 | 92 | 133 | – | – | 88.9 | 92 | 168 | 64 | 92 | 91.5 | 228.6 | 9.5 | 34.9 | 8 |

| 100 | 356 | 76.2 | 6.4 | 157 | 108 | 165 | – | – | 114.3 | 118 | 190 | 70 | 108 | 117 | 273 | 11 | 41.3 | 8 |

| 125 | 419 | 92.1 | 6.4 | 186 | 130 | 203 | – | – | 141.3 | 145 | 229 | 76 | 130 | 145 | 323.8 | 11 | 47.6 | 8 |

| 150 | 483 | 108 | 6.4 | 216 | 152 | 235 | – | – | 168.3 | 171 | 273 | 83 | 152 | 171 | 368.3 | 12.5 | 54 | 8 |

| 200 | 552 | 127 | 6.4 | 270 | 178 | 305 | – | – | 219.1 | 222 | 318 | 95 | 178 | 222 | 438.1 | 12.5 | 54 | 12 |

| 250 | 673 | 165.1 | 6.4 | 324 | 229 | 375 | – | – | 273 | 276 | 419 | 108 | 229 | 277 | 539.7 | 12.5 | 66.7 | 12 |

| 300 | 762 | 184.1 | 6.4 | 381 | 254 | 441 | – | – | 323.9 | 329.9 | 464 | 121 | 254 | 328 | 619.1 | 12.5 | 73 | 12 |

Industries we serve

Some of Our Specialities that make us a profitable Business Partner for our clients are :

We supply Flanges Worldwide.

Exporting Flanges to over 60 countries including Afghanistan, Albania, Andorra, Germany, Greece, Georgia, Hungary, Angloa, Austria, Australia, Bahrain, Bangladesh, Bhutan, Brazil, Brunei, Belarus, Belgium, Bulgaria, Cambodia, China, Cyprus, Croatia, Czech Republic, Canada, Denmark, Estonia, Egypt, Finland, France, Iceland, Ireland, Italy, Indonesia, Iran, Iraq, Israel, Japan, Jordan, Kazakhstan, Kuwait, Kyrgyzstan, Lebanon, Latvia, Latin America, Liechtenstein, Lithuania, Luxembourg, Malta, Madagascar, Mexico, Moldova, Monaco, Malaysia, Maldives, Mongolia, Myanmar (Burma), Nepal, New Zealand, North Korea, Netherlands, Norway, Nigeria, Oman, Poland, Portugal, Pakistan, Palestine, Philippines, Qatar, Russia, Romania, Russia, San Marino, Serbia and Montenegro, Slovakia, Slovenia, Spain, Sweden, Switzerland, Saudi Arabia, Singapore, South Korea, South Africa, Sri Lanka, Sudan, Syria, Taiwan, Tanzania, Tajikistan, Thailand, Turkey, Turkmenistan, Ukraine, United Kingdom, United Arab Emirates (UAE), Uzbekistan, Venezuela, Vietnam, Yemen, etc.